0102030405

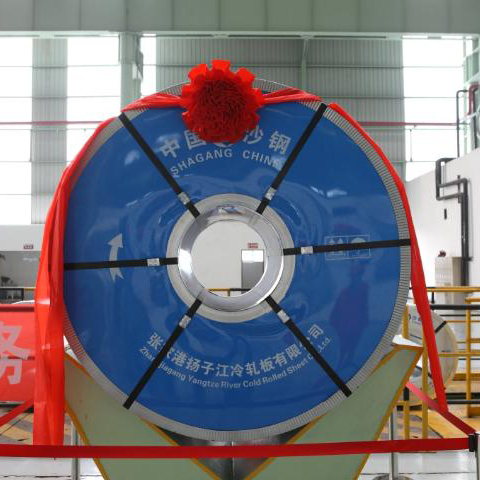

Hot-rolled wide-width stainless steel plate

description1

description

| Product name | 300 series, 400 series; |

| Product specification | 2.0~141250~2000mm; |

| Product use | The products are widely used in petroleum, chemical industry, food, large tanks, railway vehicles, containers, heat exchangers, aerospace, aviation and other industries; |

| Product features | High strength, excellent performance, fine size, full specifications, good surface; |

| Product performance | 2100mm wide hot coil annealing pickling production line, using the online rolling mill, annealing pickling and high strength extension process, can produce different strength levels of No.1,2E, THS, TSHS and other products, improve product safety; |

| Product market dynamics | With the rapid development of China's economy, industrial equipment, transportation industry products are large-scale, the demand for stainless steel wide hot plate is increasing, the stainless steel wide hot plate market demand prospect is broad. |

Hot Rolling Process:The hot rolling process involves passing a stainless steel slab through a series of rollers at an elevated temperature. This process reduces the thickness of the slab and shapes it into the desired plate form. The hot rolling technique imparts specific mechanical properties to the stainless steel, such as improved toughness, ductility, and grain structure, which contribute to the overall performance of the finished product.

Composition and Stainless Steel Grades:Hot-rolled wide-width stainless steel plates are typically made from austenitic stainless steel grades, including but not limited to 304, 304L, 316, and 316L. The selection of stainless steel grades is based on the specific requirements of the application, considering factors such as corrosion resistance, strength, and heat resistance.

Applications:

Construction and Architecture:Hot-rolled wide-width stainless steel plates find extensive use in the construction and architectural industries. They are employed in the fabrication of structural components, building facades, and other architectural elements where corrosion resistance and aesthetic appeal are essential.

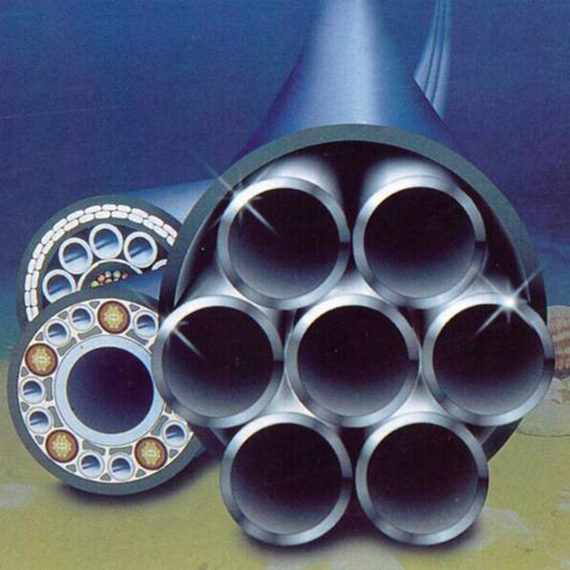

Oil and Gas Industry:In the oil and gas sector, these plates are utilized for manufacturing components such as pressure vessels, heat exchangers, and piping systems. The corrosion resistance of stainless steel is crucial in environments where exposure to corrosive substances is common.

Chemical Processing:Industries involved in chemical processing rely on hot-rolled wide-width stainless steel plates for the construction of vessels, tanks, and equipment that handle corrosive chemicals. The plates' resistance to corrosion ensures the integrity of the equipment and prevents contamination of substances being processed.

Energy Sector:Stainless steel plates play a role in the energy sector, particularly in power generation plants. They are used in the construction of boilers, heat exchangers, and other components where resistance to high temperatures and corrosive conditions is necessary.

Wide Width Advantage:The wide width of these plates offers advantages in terms of fabrication efficiency. It allows for the production of larger components with fewer welds, reducing the risk of weld-related defects and improving the overall structural integrity of the fabricated structures.

Corrosion Resistance and Longevity:Stainless steel's inherent corrosion resistance is a critical factor in the longevity of structures and components fabricated from hot-rolled wide-width stainless steel plates. This resistance ensures that the material can withstand exposure to harsh environmental conditions and corrosive substances over an extended period.

Conclusion:In conclusion, hot-rolled wide-width stainless steel plates play a vital role in various industries, contributing to the construction of durable and corrosion-resistant structures and components. The combination of the hot rolling process, stainless steel composition, and wide width enhances their suitability for a diverse range of applications, making them a fundamental material in modern industrial manufacturing.

01