0102030405

Hot rolled wear-resistand ball steel

products information

| TYPE | SPECIFICATION | STANDARD |

| LT-B2、LT-B3、LT-B4 | Φ20-110 | Bilateral technical agreement |

| HZ-B2、GN-2A-1、SGI-1、GN-3A-2 | Φ20-110 | Bilateral technical agreement |

| SGI-3、SGI-6 | Φ20-110 | Bilateral technical agreement |

| S704 | Φ20-110 | Bilateral technical agreement |

In the realm of industrial applications, the demand for durable and wear-resistant materials is paramount, especially in fields where abrasive forces and harsh conditions are prevalent. One such material that has gained prominence in various industries is hot-rolled wear-resistant ball steel. This innovative alloy represents a crucial development in materials engineering, offering exceptional hardness, toughness, and resistance to abrasion, making it an ideal choice for applications where longevity and reliability are essential.

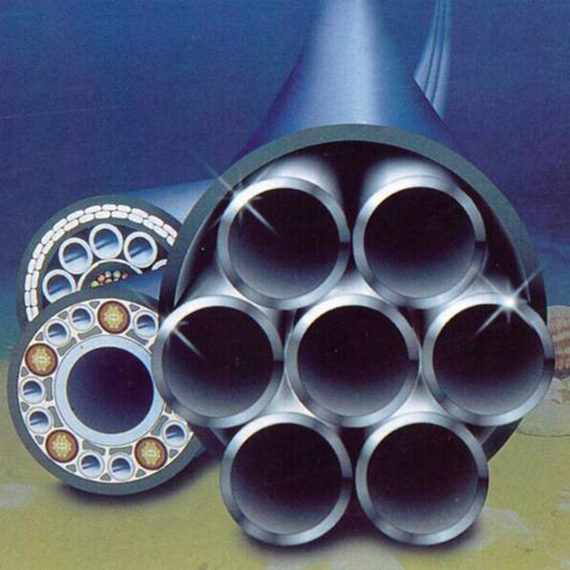

Hot-rolled wear-resistant ball steel is a specialized type of steel engineered to withstand the rigors of abrasive environments, such as mining, construction, and manufacturing processes involving crushing and grinding. The manufacturing process involves subjecting the steel to high temperatures during hot rolling, followed by controlled cooling, which imparts specific mechanical and metallurgical properties to the material. This meticulous production process results in a steel alloy with enhanced hardness and wear resistance, setting it apart from conventional steels.

The primary characteristic that distinguishes hot-rolled wear-resistant ball steel is its remarkable hardness, typically measured on the Rockwell scale. This exceptional hardness is achieved through the careful selection of alloying elements, heat treatment, and precise control of the manufacturing process. The steel's microstructure is tailored to incorporate hard phases, such as carbides, which contribute to its ability to withstand abrasive wear, impact, and heavy loads.

Applications of hot-rolled wear-resistant ball steel are diverse and span across multiple industries. In mining operations, these steel balls are utilized in crushing and grinding processes, where the ore is reduced to finer particles. Similarly, industries involved in cement production, power generation, and chemical processing benefit from the superior wear resistance of these steel balls in various machinery and equipment.

Moreover, the use of hot-rolled wear-resistant ball steel contributes to increased efficiency and cost-effectiveness in industrial processes by reducing downtime and maintenance costs associated with equipment wear. The longevity of these steel balls translates into extended service life for machinery, ultimately improving the overall productivity and profitability of industrial operations.

In conclusion, hot-rolled wear-resistant ball steel stands as a testament to the advancements in materials science, offering a solution to the challenges posed by abrasive environments in diverse industrial sectors. Its unique combination of hardness, toughness, and wear resistance makes it an indispensable component in machinery and equipment where durability is non-negotiable. As industries continue to evolve, the role of hot-rolled wear-resistant ball steel is likely to expand, providing enduring solutions to the ever-growing demands of modern applications.