0102030405

stainless seamless tube for food and catering

description1

description

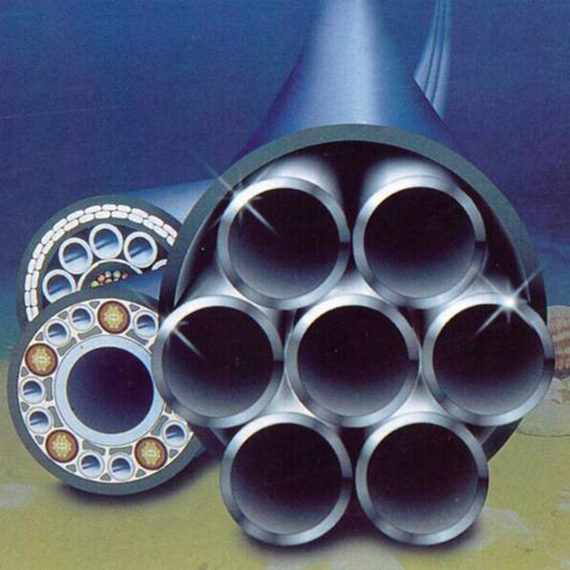

| Product specification | φ 6~7621.0~40 mm. |

| Product use | Stainless steel seamless pipe is widely used in petroleum and petrochemical, oil and natural gas exploitation, power station boiler, power generation, shipbuilding and other important fields; |

| Product characteristics | Product chemical composition, stable performance, is the domestic petroleum and petrochemical, power station boiler enterprises designated to use products; |

| Product performance | Non-metallic inclusions, low gas content, high steel purity, uniform and stable chemical composition, with good service performance (corrosion resistance, mechanical properties, high temperature performance), processing performance (cold processing performance, thermal processing performance); |

| Product market dynamics | TISCO 50,000 tons of stainless steel seamless steel pipe project will replace the import of large diameter thick wall seamless steel pipe. |

1. Material:

Stainless Steel: The tube is made from stainless steel, which is a corrosion-resistant and durable alloy. Common stainless steel grades used for tubes include 304 (most common), 316, 321, and others, each with specific properties suited for different applications.

2. Manufacturing Process:

Welding: The tube is formed through a welding process, which involves joining two pieces of stainless steel using heat and pressure. There are different welding techniques employed, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or other methods, depending on the specifications and requirements.

3. Size and Dimensions:

Diameter: The tubes come in various diameters, ranging from small sizes suitable for precision applications to larger diameters for heavy-duty industrial use.

Thickness: The thickness of the tube's walls can vary based on the intended use. Thicker walls provide greater strength and durability.

4. Surface Finish:

Polished or Unpolished: Depending on the application, the surface of the tube may be polished to achieve a smooth, shiny finish or left unpolished for specific industrial or structural purposes.

5. Application:

Versatility: Welded stainless tubes find applications in a wide range of industries, including construction, automotive, petrochemical, food and beverage, pharmaceuticals, and more. They are used for conveying fluids, gases, or as structural components.

6. Corrosion Resistance:

Stainless Steel Properties: One of the key advantages of using stainless steel is its excellent resistance to corrosion, making it suitable for applications where exposure to moisture or corrosive substances is a concern.

7. Standards and Specifications:

Compliance: Depending on the application and industry, welded stainless tubes may need to adhere to specific standards and specifications, such as ASTM (American Society for Testing and Materials) standards or other international standards.

8. Cost and Availability:

Economic Considerations: The cost of welded stainless tubes can vary based on the grade of stainless steel, size, and other specifications. They are generally available from suppliers and manufacturers specializing in stainless steel products.

In summary, welded stainless tubes are versatile, durable, and corrosion-resistant products used in various industries for conveying fluids, structural support, and other applications where the properties of stainless steel are advantageous.

Composition and Stainless Steel Grades:Stainless seamless tubes are predominantly manufactured from austenitic stainless steels, which contain significant amounts of chromium and nickel. The most common stainless steel grades used in the production of seamless tubes include 304, 304L, 316, and 316L. These alloys offer excellent corrosion resistance, even in harsh environments, due to the formation of a passive oxide layer on the steel's surface.

Seamless Manufacturing Process:The seamless manufacturing process distinguishes these tubes from their welded counterparts. Seamless tubes are produced by piercing a billet or a solid bar to create a hollow tube. This process ensures a uniform structure without the presence of weld seams, resulting in a tube with enhanced strength and resistance to pressure, especially in high-temperature and high-pressure applications.

Applications:Stainless seamless tubes find widespread use in a variety of industries due to their unique combination of corrosion resistance, strength, and versatility. In the oil and gas sector, these tubes are utilized for conveying fluids in pipelines, where resistance to corrosive elements is crucial. In the chemical processing industry, stainless seamless tubes are employed for transporting chemicals and corrosive materials.

The aerospace industry relies on these tubes for applications such as hydraulic systems and structural components, where the material's strength-to-weight ratio is vital. Additionally, in the pharmaceutical and food processing industries, stainless seamless tubes are preferred for their hygienic properties, making them suitable for transporting liquids and gases without the risk of contamination.

Corrosion Resistance:One of the primary advantages of stainless seamless tubes is their exceptional corrosion resistance. The chromium content in stainless steel forms a passive oxide layer that protects the material from corrosive elements, including acids, salts, and moisture. This resistance to corrosion ensures a longer service life and minimizes maintenance requirements.

Conclusion:In conclusion, stainless seamless tubes represent a pinnacle in materials engineering, providing a durable and corrosion-resistant solution for various critical applications. Their seamless manufacturing process, combined with the inherent properties of stainless steel, makes them a reliable choice for industries that demand high-performance materials. As technology advances, the role of stainless seamless tubes is likely to expand, contributing to the development of more efficient and durable infrastructure across diverse sectors.

01