0102030405

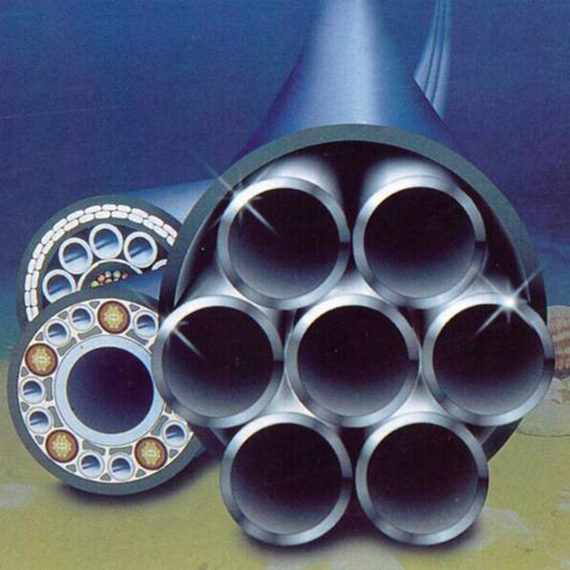

Microwire, filament stainless steel coil

description1

description

| Product name | 304L, SUS304HC, 304S, 00Cr17Ni14Mo2,0Cr18Ni9LS, 0Cr18Ni9Y, Cr series products, etc.; |

| Product specification | φ 5.5mm |

| Product use | Stainless steel filament and microfilament products are widely used in non-woven fabric, body armor; petroleum, chemical, food, medicine, aerospace, aviation and other industries filter; IT industry precision spring winding; |

| Product features | Using molten iron as raw material, vacuum refining, harmful inclusion elements, low gas content, high steel purity; large furnace capacity, large compression ratio, uniform and stable chemical composition, good extension performance; |

| Product performance | Corrosion resistance, good extension performance, small processing hardening, low mold loss rate; |

| Product market dynamics | With the rapid development of China's economy, stainless steel filament, microwire are widely used in various fields of production and life, the market prospect is broad. |

Microwire:Microwire typically refers to a very thin wire, often with a diameter measured in micrometers or millimeters. Stainless steel microwire is engineered to exhibit specific physical and mechanical properties, making it suitable for applications requiring precision and miniaturization. The manufacturing process involves drawing the stainless steel through progressively smaller dies to achieve the desired diameter. The resulting microwire is characterized by its high strength, corrosion resistance, and suitability for intricate applications.

Filament Stainless Steel Coil:A filament is a long, thin thread or wire. In the context of stainless steel, a filament stainless steel coil refers to a coiled arrangement of such thin wires or filaments. These coils are produced by winding the stainless steel filaments around a central core. The coiling process enhances the flexibility and strength of the stainless steel, making it suitable for applications where both of these properties are crucial.

Applications:

Electronics and Microelectronics:Microwire and filament stainless steel coils are used in electronics and microelectronics for various applications, including microfabrication, sensors, and miniaturized components. Their small diameter and excellent conductivity make them ideal for intricate electronic circuits and devices.

Medical Devices:In the medical field, these coils are employed in the manufacturing of medical devices such as guidewires, catheters, and sensors. The corrosion resistance and biocompatibility of stainless steel are essential in medical applications, ensuring the safety and longevity of the devices.

Industrial Processes:Filament stainless steel coils are utilized in industrial processes where precise control and durability are critical. They can be incorporated into machinery and equipment for tasks such as cutting, heating, or sensing, depending on the specific requirements of the process.

Heating Elements:The high resistance to heat and corrosion of stainless steel makes it suitable for heating applications. Stainless steel filament coils can be used as heating elements in various appliances, from small heating devices to industrial furnaces.

Corrosion Resistance:The corrosion resistance of stainless steel is a key attribute that makes microwire and filament coils suitable for many applications. This property ensures that the wire remains intact and reliable even in harsh environments or when exposed to corrosive substances.

Conclusion:Microwire and filament stainless steel coils exemplify the adaptability and precision achievable through metallurgical engineering. Their use in electronics, medical devices, and industrial processes underscores their importance in advancing technology and manufacturing. As industries continue to demand miniaturization and precision, these specialized stainless steel coils are likely to play an increasingly significant role in various applications.

01