0102030405

Welded stainless tube for construction

description1

description

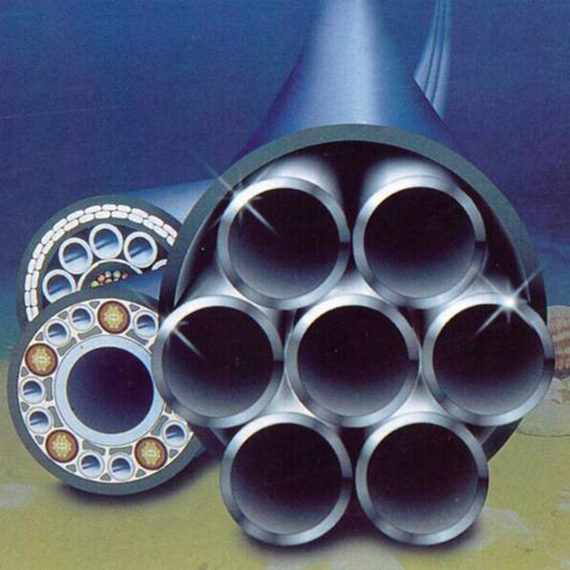

| Product specification | φ 12.7~4800mm 1.0~50 mm. |

| Product use | Stainless steel welded steel pipe is widely used in petroleum and petrochemical, oil and natural gas exploitation, power station boiler, power generation, shipbuilding and other important fields; |

| Product characteristics | Product chemical composition, stable performance, is the domestic petroleum and petrochemical, power station boiler enterprises designated to use products; |

| Product performance | Non-metallic inclusions, low gas content, high steel purity, uniform and stable chemical composition, with good service performance (corrosion resistance, mechanical properties, high temperature performance), processing performance (cold processing performance, thermal processing performance); |

| Product market dynamics | With the further increase of investment in the field of energy development, reserve and transportation, the demand for stainless steel welded pipe will also increase greatly, and the stainless steel welded pipe market has great potential. |

Material Composition and Grades:Welded stainless steel tubes for construction are typically made from austenitic stainless steel grades, such as 304, 304L, 316, and 316L. These grades are chosen for their excellent corrosion resistance, high strength, and formability. The alloying elements, including chromium and nickel, contribute to the formation of a protective oxide layer on the steel's surface, enhancing its resistance to corrosion in diverse environmental conditions.

Welding Process:The tubes are manufactured through the welding process, which involves joining two pieces of stainless steel using various welding techniques. Common welding methods for stainless steel tubes include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and laser welding. The welding process ensures a strong and consistent bond between the steel sheets, creating a tube that can withstand structural loads and environmental stresses.

Structural Applications:Welded stainless steel tubes are extensively used in construction for structural applications. They are employed in the fabrication of columns, beams, and braces, providing essential support and stability in buildings and infrastructure. The tubes contribute to the overall structural integrity of the construction, especially in applications where resistance to corrosion and environmental factors is crucial.

Corrosion Resistance:One of the primary advantages of using welded stainless steel tubes in construction is their exceptional corrosion resistance. This resistance is vital in construction projects where exposure to moisture, chemicals, and varying weather conditions can lead to the degradation of materials over time. Stainless steel's corrosion resistance ensures the longevity of the tubes and minimizes maintenance requirements, contributing to the sustainability of construction projects.

Versatility and Adaptability:Welded stainless steel tubes are available in various sizes, shapes, and thicknesses, offering versatility in construction applications. They can be customized to meet specific design requirements and are adaptable to different construction methods. This flexibility makes them suitable for a wide range of projects, including residential buildings, commercial structures, and infrastructure developments.

Conclusion:In conclusion, welded stainless steel tubes for construction play a crucial role in providing structural stability, corrosion resistance, and versatility in building projects. Their use contributes to the overall durability and longevity of structures, making them a preferred choice for architects, engineers, and builders. As construction technology advances, the role of welded stainless steel tubes is likely to expand, offering innovative solutions for the evolving needs of the construction industry.

01