0102030405

High precision pinion steel

product information

| Brand | American brand | Japanese brand |

| 16MnCr(S)5、20MnCr(S)5、20MnCr5HH、20MnCSr5HH | ||

| SCM415(H)、SCM420H、20CrMo(H)、31CrMoV9、42CrMoS4HH | 4118H、4130H4140H、4150H | SCM415H、 SCM420HSCM822H,、SCM440H |

| 16CrMnBH、17CrMnBH、18CrMnBH | ||

| 17CrNiMo6、18CrNiMo7-6、340rNiMo6 | ||

| 20CrMnTiH、20CrMnTiH1-H5 | ||

| 20CrH | SCr420H | |

| 20CrNiMoH、22CrNiMoH、27CrNiMoH | SAE8620H、8622H8627H、 8620H | SNCM220H |

| 20CrMnMo | ||

| 19CrNi5 |

Composition and Properties:Pinion steel is typically a high-quality alloy steel that undergoes careful selection of alloying elements to achieve specific mechanical properties. Common alloying elements include carbon, manganese, chromium, nickel, and molybdenum. The precise composition is tailored to provide a balance of hardness, toughness, and fatigue resistance, all crucial factors for the demanding conditions that gears and pinions encounter during operation.

The microstructure of pinion steel is often refined through heat treatment processes like quenching and tempering. This enhances its mechanical properties, ensuring the material can withstand the stresses, loads, and friction associated with gear engagement.

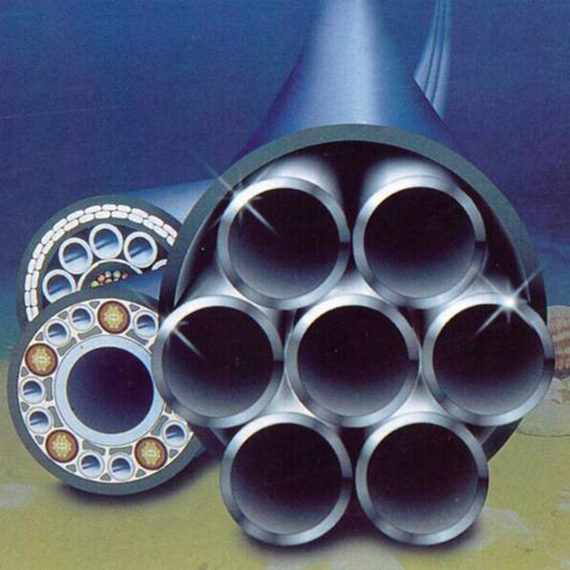

Applications:Pinion steel finds applications across a wide range of industries where gear systems are integral to mechanical operations. In automotive engineering, pinion steel is utilized in the manufacturing of gear sets for transmissions, differential systems, and steering mechanisms. Its ability to withstand repeated loading, resist wear, and maintain dimensional stability is essential for the longevity and efficiency of these components.

In industrial machinery, pinion steel is employed in gear systems for equipment such as conveyors, cranes, and various types of machinery where precise power transmission is crucial. The material's durability and resistance to wear contribute to the overall reliability and productivity of these systems.

Precision Engineering:The precision required in gear systems, especially in applications like robotics and aerospace, demands high-quality materials like pinion steel. The material's uniformity and consistency in terms of hardness and mechanical properties are critical for ensuring smooth and reliable gear engagement.

Conclusion:In conclusion, pinion steel stands as a specialized material designed to meet the unique challenges posed by gear and pinion applications. Its carefully engineered composition and heat treatment processes result in a material that excels in durability, wear resistance, and precision, making it an indispensable component in the machinery that powers various industries. As technology advances, the role of pinion steel continues to evolve, contributing to the development of more efficient, reliable, and precise mechanical systems.