01

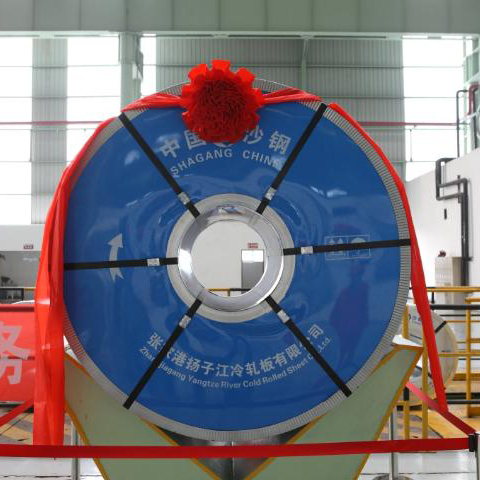

Cold rolled steel coil ASTM A1008

production

The production of cold rolled steel begins with hot rolled steel that has been pickled to remove scale and other impurities. The pickled steel is then rolled at room temperature through a series of stands to achieve the desired thickness and shape. The final product is a steel coil that has been work-hardened and annealed to achieve the desired mechanical properties.

One key advantage of cold rolled steel is its improved surface finish, which is smoother and more uniform than hot rolled steel. This makes it an ideal choice for applications that require a high-quality surface, such as painted or coated products. Cold rolled steel also has better dimensional tolerances than hot rolled steel, making it easier to work with and more suitable for applications that require tight tolerances.

specification

Here is an example of a specification form for a cold rolled steel coil:

| Product | Cold Rolled Steel Coil |

| Grade | SAE 1006 |

| Thickness | 0.8 mm |

| Width | 1000 mm |

| Coil ID | 508 mm |

| Coil OD | 1600 mm |

| Coil Weight | 10 MT |

| Surface Finish | Bright, smooth |

| Edge Condition | Mill Edge |

| Packaging | Standard Export Packing |

| Application | Automotive components, appliances, furniture |

This specification form provides key details about the cold rolled steel coil, including its grade, thickness, width, coil dimensions, surface finish, and intended application. It serves as a reference for buyers and suppliers to ensure that the product meets the required standards and specifications.